company-profile-module $!{companyProfile}

Automatic Thermal Insulation Mineral Rock Basalt Wool Production Line

Popular

Popular in

FOB Reference Price:Get latest price

-

>=1 Sets

$1,000,000.00

- Inventory Status:

-

In Stock

- Lead time:

-

Quantity(Sets) 1 - 1 >1 Lead time (days) 180 Negotiable

Product details

Company profile

Overview

Essential details

- Video outgoing-inspection:

-

Provided

- Machinery Test Report:

-

Provided

- Core Components:

-

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

- Application:

-

Thermal Fire protection Sound absorption

- Automatic Grade:

-

Automatic

- Production Capacity:

-

10000-60000

- Place of Origin:

-

Hebei, China

- Brand Name:

-

Guangxing

- Voltage:

-

380V

- Power:

-

1000 KW

- Weight:

-

200000 kg

- Features:

-

High efficiency, environmentally friendly

- Warranty:

-

5 years

- Key Selling Points:

-

Easy to Operate

- Product name:

-

Rock Wool Production Line

- Raw material:

-

Basalt\Additive-Dolomite

- Utility requirements:

-

natural gas\Water\electricity

- Panel Thickness:

-

20-250mm

- Felt Size:

-

1000mm (adjustable)

- Panel Density:

-

30-200 kg/m³

- Widths:

-

600-2400 mm

- Line speeds:

-

2-40 m/min

- Capacities:

-

4-8 t/h final product

- Finished products:

-

Boards, felts, stitched mats, pipe sections, reinforced cords

- Showroom Location:

-

India, Russia

- Marketing Type:

-

New Product 2020

- Warranty of core components:

-

5 years

- Condition:

-

New

- Applicable Industries:

-

Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works , Other

Packaging & delivery

- Lead time :

-

Quantity(Sets) 1 - 1 >1 Lead time (days) 180

Online Customization

Video Description

Products Description

Product name | Rock Wool Production Line |

Automatic Grade | Automatic |

Voltage | 380V |

Features | Automatic |

Panel Thickness | 30-150mm |

Felt Size | 1000mm (adjustable) |

Panel Density | 30-200 Kg/m3 |

Applicable Industries | Manufacturing Plant, Retail, Construction works |

Finished products | rock wool mattress and board |

Usage | Building Material Production |

Rock wool products are mainly made of high-quality basalt, dolomite, and other raw materials. After high-temperature melting, they are centrifuged into fibers using a four axis centrifuge at high speed. At the same time, a certain amount of binder, dustproof oil, and water repellent are sprayed into them. After being collected by a fiber collector, they are cured and cut using a pendulum method and three-dimensional fiber laying method, forming rock wool products of different specifications and purposes.Due to the fact that rock wool products are artificial inorganic fibers processed through high-temperature melting, they have the characteristics of light weight, low thermal conductivity, heat insulation, and flame retardancy, and are widely used in various industries.

Rock wool product | Density(Kg/m³) | Size | ||||

Length(mm) | Width(mm) | Thickness(mm) | ||||

Panel | 30-200 | 1000(Adjustable) | 600-2400 | 20-250 | ||

Felt | 30-200 | 1000(Adjustable) | 600-2400 mm | 30-100 | ||

Pipe | Density(Kg/m³) | Length(mm) | Diameter(mm) | Thickness(mm) | ||

30-200 | 1000 | Φ20-Φ630 | 30-100 | |||

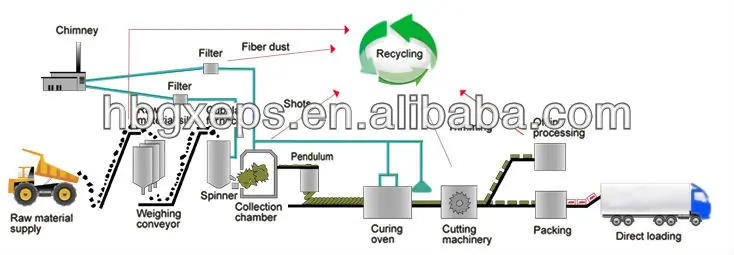

Raw materials(stones) will be transported to the site by truck, stored under a roof, and conveyed indoors via enclosed conveyors to silos.The materials are individually weighed and mixed before entering the furnace.

The melt flows from the furnace and is applied to the spinning wheels. Fibers are drawn from the spinning wheels with a powerful airflow and injected into the spinning chamber.

The mineral wool is uniformly layered into the desired thickness. Then, depending on the product (batts or boards), the mineral wool fibers are set up as either single or dual density.

In the cutting area, vertical cuts can be made into standard dimensions of 60cm.We have two machine specifications available, which are 1.2m and 2.4mrespectively.

The products are stacked, wrapped in polyethylene film, and palletized before being transported to the finished goods storage area.

1 | Raw material system | 1)Feeding system 2) Automatic proportioning machine 3)Control cabinet (PLC is adopted) 4)Feeding machine |

2 | Melting system | 1) Furnace platform 2)Cupola furnace 3) Material level control system 4)Dust catcher 5)Waste gas burning furnace 6)Waste gas intake pipe 7)Waste gas intake fan 8)Heat exchanger 9)Control cabinet 10) Melting furnace cooling system 11)Wind supply fan for the melting furnace 12)Wind supply pipeline for melting furnace |

3 | Wool making system | 1) High speed centrifuge 2)Fan 3)Fiber blowing bellows 4)Lubricating system of centrifuge 5)Water pump and water cooling system 6)Electrical control cabinet(PLC) 7) Residue-remover |

4 | Rock wool resin-spraying system | 1)Laser tracking system of lava 2)Metering pump 3)Nozzle for resin diffusion 4)Control cabinet |

5 | Wool collecting and allocation system & Board making system | 1)Wool collector and Pendulum wool allocation machine 2) Control cabinet 3) Air-intake fan for wool collecting 4)Dust filtering system of wool collecting part 5) Wool allocation conveyer 6)Compressing pleating machine 7) Curing oven 8)Main power assembly 9) Control cabinet |

6 | Curing oven explosion-proof system | 1) Natural gas inspect system 2)Explosion-proof fan 3)Explosion-proof pipes 4)Control cabinet |

7 | Cutting system | 1)Cooling conveyor 2) Cooling fan 3) Thickness saw 4)Cooling cutter 5)Metering device of cutting 6)Control cabinet 7)Cutting machine driving system |

8 | Dust-removing system of cutting part | 1)Bag-type dust filter 2)Dust-removing pipes 3)Dust-removing fan |

9 | Curing oven hot blast system | 1) Heat-resisting fan 2)Hot blast furnace 3)Burner 4)Hot wind pipes |

10 | Scrap recycling machine | 1)Crusher 2)Scrap-recycling fan 3) Scrap-recycling pipeline |

Applications

Recommend Products

Company Profile

Hebei Guangxing Machinery Technology Co., Ltd. was founded in 1987. It is a professional manufacturer of exterior wall insulation equipment and composite panel equipment. It is the largest and most competitive enterprise in the same industry in China.

The rock wool production line, polyurethane rock wool color steel composite panel production line and EPS phenolic foam production line developed by our company have all reached the international advanced level and have passed ISO9001 quality management system certification. The products sell well in more than 30 provinces, cities and autonomous regions, and are exported to Europe, Central Asia and Southeast Asia. With first-class technology and first-class products, the company provides customers with high-quality services from product design, research and development, production, installation training to after-sales. It is regarded by the majority of users as an excellent enterprise that "keeps its promise and values service", and has been awarded the famous brand product of Hebei Province. welcome experts, friends, new and old customers from all walks of life to patronize and communicate with us to create brilliance and win-win future together.

Customer Photos

Shipping

FAQ

Q: Where is the factory located?

A: We are located in Xinji, Hebei Province, near Beijing airport. You could fly to Beijing Airport, we could pick you there.

Q: Do you accept on-site inspection to check your machine and your factory?

A: Before shipment, every equipment will be trail tested in our factory, we invite all the client to do on-site inspection during

trail testing.

Q: What payment terms do you prefer?

A: T/T, L/C, West Union, Cash etc.

Q:How long is the validity of quotation?

A:Generally, our price is valid within one month from the date of quotation . The price will be adjusted appropriately according to the price fluctuation of raw materials and changes in market .

Q:What is your delivery time?

A:Usually, we make merchandise inventory, if we have the products in stock, the delivery time is 5-10 days after receiving the deposit. If we don't have the products in stock, we will arrange the production right now, the delivery time will be 1-3

month,It depend on the order quantity.

Q:Do you provide OEM/ODM Service?

A:Yes, offer me necessary information, we provide custom-make service to meet different needs of global clients with different budgets.

Q:How can we ensure quality?

A:The final inspection is always carried out before shipment.

Q:How to install the equipment after purchasing?

A:We will provide a professional installation video to illustrate.Also provide a manual.

Q:Do you offer a guarantee?

A:Yes, we guarantee our product for one year. Provide after-sales service support with and agricultural technical support.

Q:What is your MOQ?

A:1Sets

A: Before shipment, every equipment will be trail tested in our factory, we invite all the client to do on-site inspection during

trail testing.

Q: What payment terms do you prefer?

A: T/T, L/C, West Union, Cash etc.

Q:How long is the validity of quotation?

A:Generally, our price is valid within one month from the date of quotation . The price will be adjusted appropriately according to the price fluctuation of raw materials and changes in market .

Q:What is your delivery time?

A:Usually, we make merchandise inventory, if we have the products in stock, the delivery time is 5-10 days after receiving the deposit. If we don't have the products in stock, we will arrange the production right now, the delivery time will be 1-3

month,It depend on the order quantity.

Q:Do you provide OEM/ODM Service?

A:Yes, offer me necessary information, we provide custom-make service to meet different needs of global clients with different budgets.

Q:How can we ensure quality?

A:The final inspection is always carried out before shipment.

Q:How to install the equipment after purchasing?

A:We will provide a professional installation video to illustrate.Also provide a manual.

Q:Do you offer a guarantee?

A:Yes, we guarantee our product for one year. Provide after-sales service support with and agricultural technical support.

Q:What is your MOQ?

A:1Sets

You May Like

Not exactly what you want? 1 request, multiple quotations Get Quotations Now >>

You May Like

For more detailed information including pricing, customization, and shipping:

Contact supplier

Call Us

Call Us

Call Us

Call Us

Manufacturer, Trading Company

|

≤2h

Response Time

The average amount of time supplier took to respond to every buyer’s first message over the past 30 days.

|

|

| On-time delivery rate |